INDUSTRIAL EQUIPMENT

The cost of equipment failure can potentially be huge. All industries rely on equipment to function. As a manufacturer, ensuring your products function as per the design scope is crucial. As a user, you must ensure your equipment is fit for purpose and well maintained.

The cost of equipment failure can potentially be huge. All industries rely on equipment to function. As a manufacturer, ensuring your products function as per the design scope is crucial. As a user, you must ensure your equipment is fit for purpose and well maintained.

The cost of equipment failure can potentially be huge. All industries rely on equipment to function. As a manufacturer, ensuring your products function as per the design scope is crucial. As a user, you must ensure your equipment is fit for purpose and well maintained.

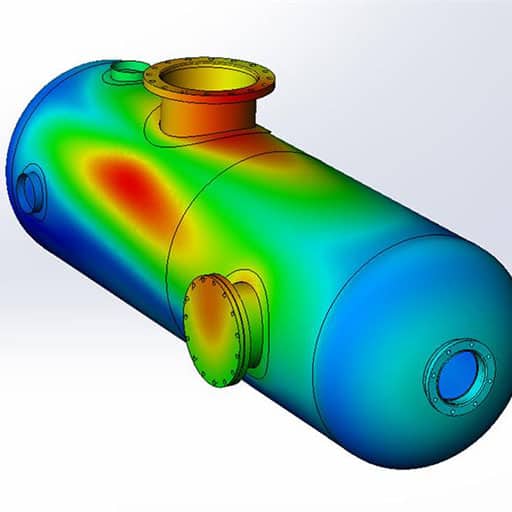

For regulated industries (Petrochemicals, Oil & Gas and Nuclear), adherence to design codes is essential and defines product or system robustness. For other industries, and where regulatory codes do not offer guidance, a sensible understanding of performance and potential failure modes is required to set the criteria for robust design. In all cases, the use of Advanced Engineering methods such as FEA and CFD is key to your success.

What is an example of industrial equipment?

Examples of “industrial fixtures” are fuel oil lines, boilers, craneways, and certain concrete slabs. “Device” is an item that is not attached to the building or site. Examples of devices are: Forklifts, chainsaws, air compressors, clamps, free standing shelving, software, ladders, wheelbarrows, and pulleys.

Call For a Quote:

+44(0)7550680067

Related Services

STATIC EQUIPMENT

ROTARY EQUIPMENT

F.A.Q.

What is the purpose of asset integrity management system?

Asset integrity management ensures you have the business processes, systems, tools, competence and resources you need to ensure integrity throughout the asset lifecycle. Design, operational, and technical integrity must all be managed effectively to control costs.

How do you maintain asset integrity?

An effective asset integrity management programme requires continuous monitoring and inspection to take place, and typically includes proactively inspecting assets to identify potential failures. The programme should feature regular inspections and testing, non-destructive testing, and continuous monitoring systems.

What is asset integrity process safety?

The terms ‘process safety’ and ‘asset integrity’ are both used throughout the petroleum industry, often synonymously. For the oil and gas industry the emphasis of process safety and asset integrity is to prevent unplanned releases which could result in a major incident.

What is the difference between asset integrity and reliability?

In a nutshell, Reliability is a measure of an asset ability to perform its intended function under designed conditions for the specified period of time. Asset Integrity is a more a condition monitoring of the assets using the NDT and Asset Integrity Techniques to avoid unplanned failures.

What is the main function of asset management?

Asset managers help protect investments by spreading them out across various types of stocks, bonds and other financial products. This diversification is especially important at times of economic uncertainty and high inflation.