FITNESS FOR SERVICE ANALYSIS

Industry

Petro Chemical

Service

Petro Chemical

Expertise

Petro Chemical

Background

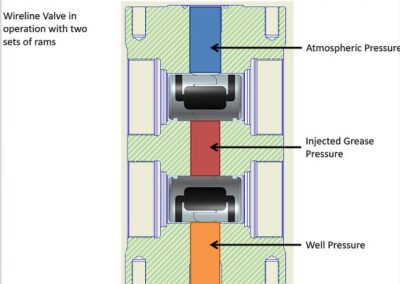

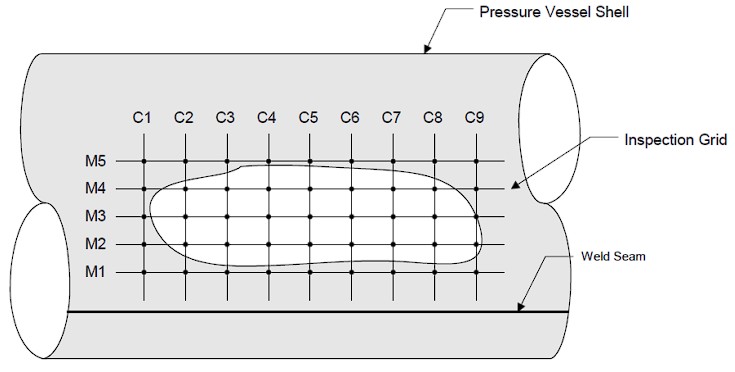

• Separator nozzle N1 was suffering from crevice corrosion due to moisture ingress via the weep hole in the reinforcement pad.

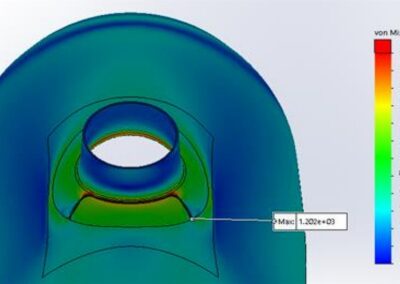

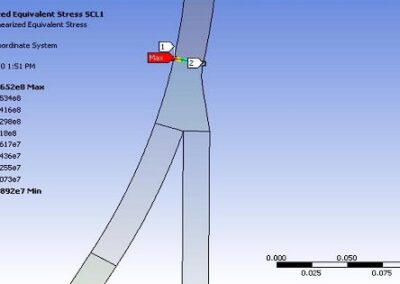

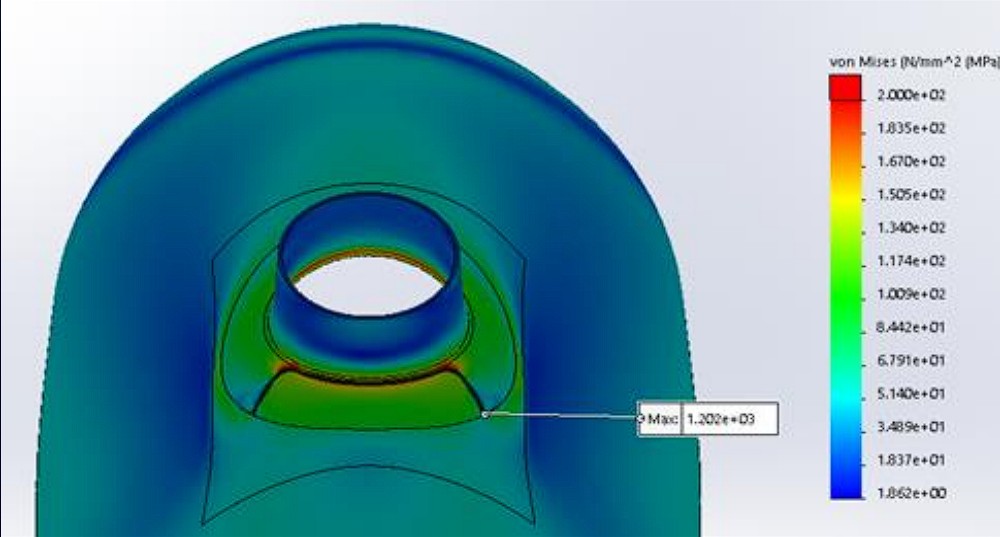

• Preliminary code calculations were not fully conclusive as to the fitness for service of this item and therefore a Level 3 assessment using a linear elastic Finite Element Analysis (FEA) model was built.

Outcomes

- The maximum stress utilisation was evaluated to be 91.8% and is based on the

current estimated remaining wall thickness (RWT) of 9.6mm with no future corrosion

allowance (FCA) included. - The nozzle was verified against the loads provided by operator and found to be fit for

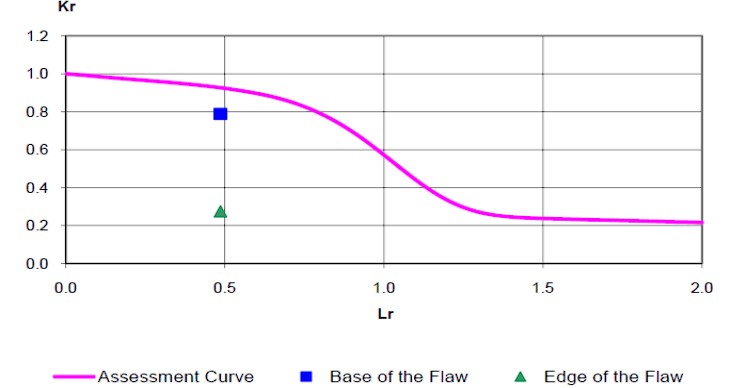

service in the current state. - The fracture mechanics assessment revealed on the FAD that the equipment was

safe.

Challenges

• Bespoke geometry of the cut-out in the nozzle pad had to be modelled.

• Low cycle fatigue evaluation required using fracture mechanics approach