Computational Fluid Dynamics (CFD)

We employ CFD analysis in a variety of applications, enhancing oil & gas engineering consultancy capabilities:

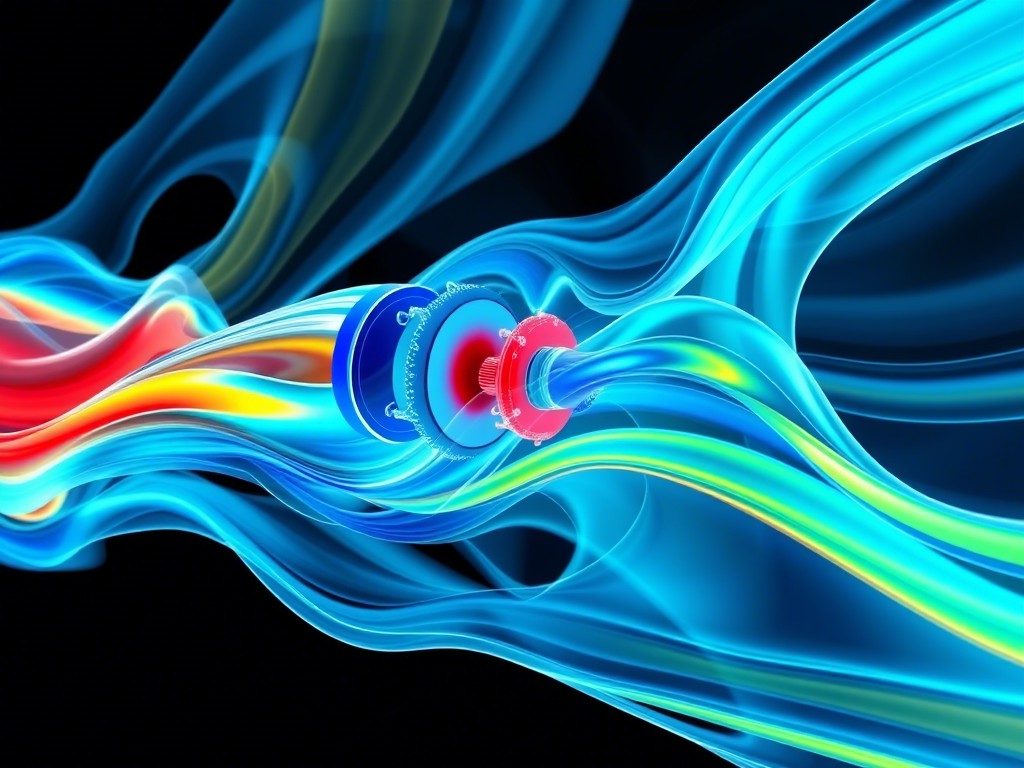

- Heat exchangers and cooling systems for industrial processes.

- Aerodynamics and hydrodynamics for vehicles, turbines, and pipelines.

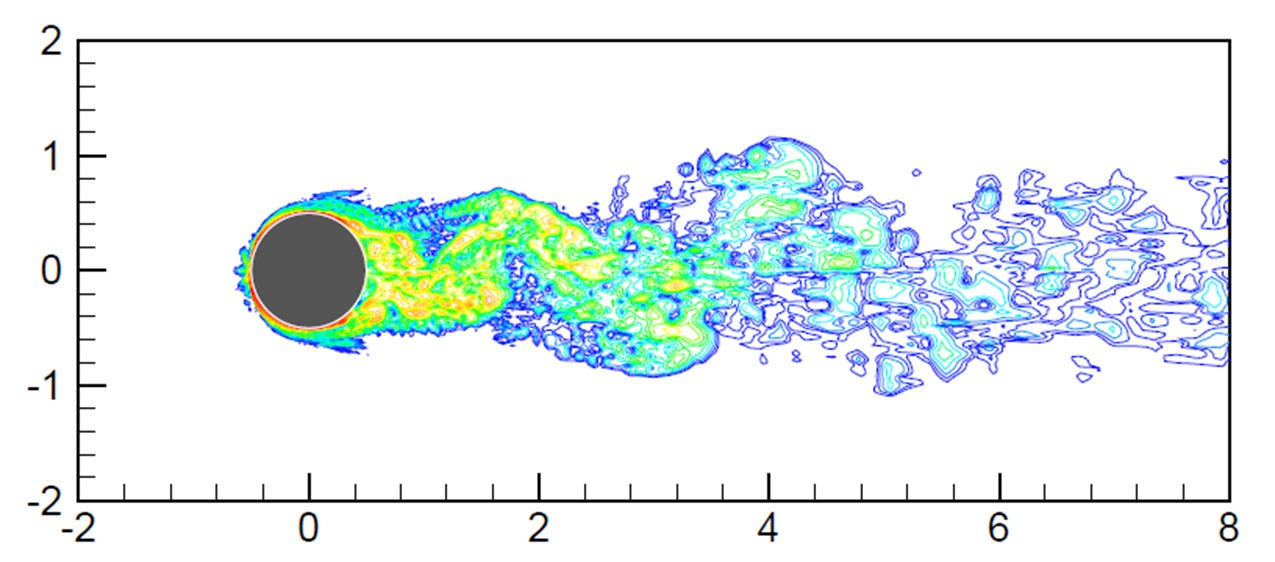

- Multi-phase and turbulent flow simulations for optimized performance.

- Combustion and chemical process simulations for efficiency improvements.

- Flow Assurance Studies ensuring efficient operation of complex piping and pressure systems.

- HVAC System Design Optimization to enhance energy efficiency in industrial environments.

What is Computational Fluid Dynamics?

Call For a Quote:

+44(0)7550680067

F.A.Q.

What are the key benefits of CFD analysis?

-

Cost Savings: Reduces reliance on physical prototypes.

-

Speed: Accelerates design iterations and troubleshooting.

-

Insight: Visualizes complex flow patterns (e.g., vortices, thermal gradients).

-

Safety: Simulates extreme conditions (e.g., high temperatures, chemical reactions) without risk.

Which industries use CFD simulations?

CFD is critical in:

-

Aerospace (aircraft aerodynamics, combustion analysis).

-

Automotive (vehicle drag reduction, battery cooling).

-

HVAC (ventilation system design).

-

Oil & Gas (pipeline flow optimization).

-

Renewable Energy (wind turbine performance).

What software do you use for CFD simulations?

e leverage industry-leading tools like ANSYS Fluent, COMSOL Multiphysics, OpenFOAM, and STAR-CCM+ for accurate modeling of laminar/turbulent flow, multiphase systems, and heat exchangers.