Pressure Vessel Analysis

Cygnas delivers precision pressure vessel analysis services, ensuring compliance with ASME, EN, and API standards while optimizing safety and performance.

We provide advanced pressure vessel design and analysis to ensure compliance with ASME, API, and international safety standards. Our engineering consultancy services in this domain include:

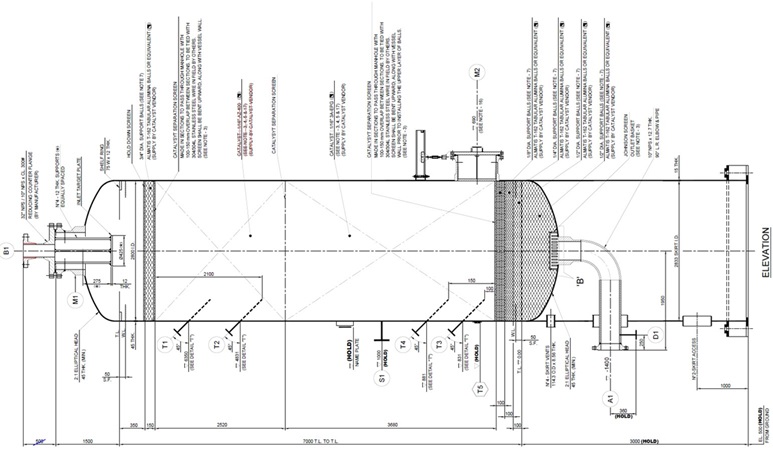

- Design validation and optimization for cost-effective, high-performance vessels.

- Structural integrity assessment to ensure long-term operational safety.

- Fatigue and fracture mechanics evaluation for identifying potential failure points and extending service life.

- Thermal stress analysis to predict temperature-induced deformations and failure risks.

- Fitness-for-service assessments and failure analysis for industrial pressure vessels.

What is Pressure Vessel Analysis?

Pressure Vessel Analysis is a specialized engineering evaluation process that ensures the safe design, operation, and compliance of containers holding gases or liquids under significant pressure.

Call For a Quote:

+44(0)7550680067

F.A.Q.

Feel Free to ask any questions you might have.

Why is pressure vessel analysis critical?

Pressure vessel analysis ensures compliance with safety standards (e.g., ASME BPVC, PED), prevents catastrophic failures, and optimizes design for cost-efficiency. It evaluates stress, fatigue, and material suitability under operational conditions.

What standards do you follow for analysis?

We adhere to global standards, including ASME Boiler and Pressure Vessel Code (BPVC), EN 13445 (PED), and API 510/579. Our team ensures compliance with local regulations for your region.

How long does a typical analysis take?

Timelines vary based on complexity, but most projects are completed in 2–6 weeks. We prioritize urgent requests while maintaining rigorous quality checks.

Do you handle both design validation and existing vessel assessments?

Yes. We offer:

- Design-phase FEA (Finite Element Analysis) for new vessels.

- Integrity assessments for aging or damaged vessels, including corrosion and crack evaluations.