Finite Element Analysis (FEA)

Cygnas delivers advanced FEA solutions to simulate structural, thermal, and dynamic performance—optimizing designs for strength, efficiency, and reliability. Our expertise helps industries reduce prototyping costs, validate safety, and accelerate innovation. From component-level analysis to full-system simulations, we turn complex physics into actionable insights.

Finite Element Analysis (FEA) is crucial in evaluating structural integrity and predicting performance under real-world conditions. Our finite element analysis services include:

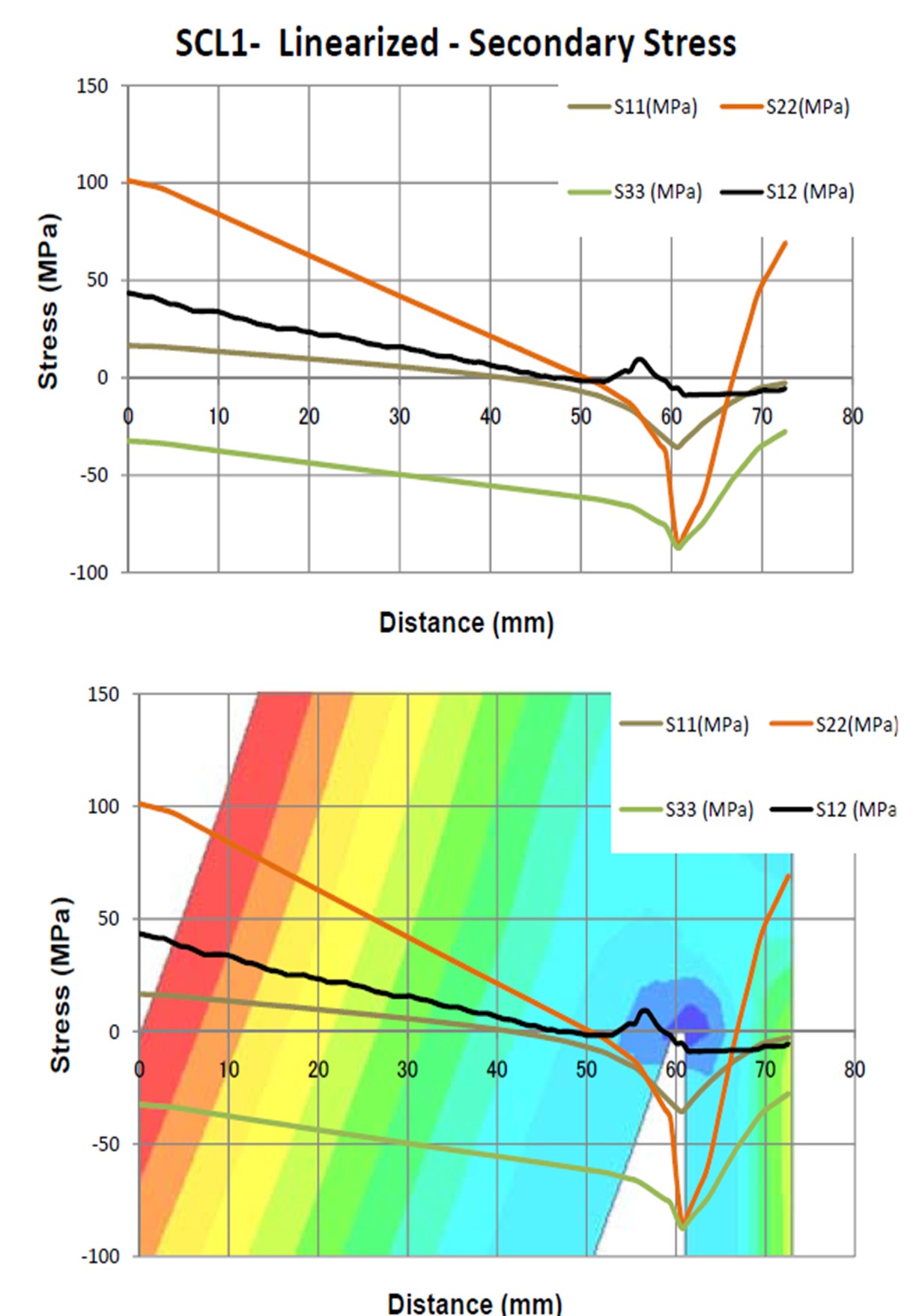

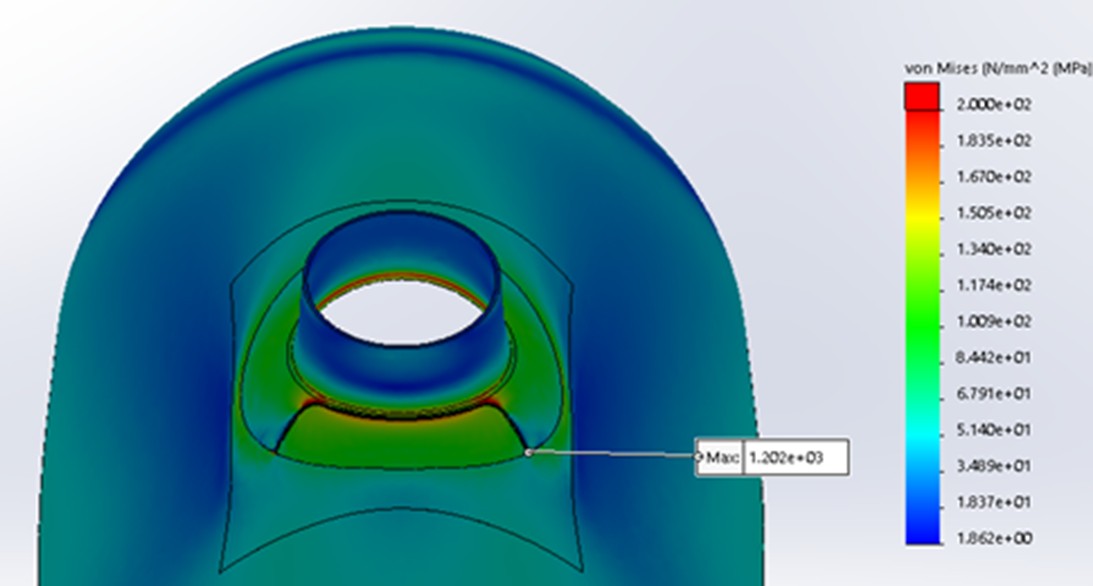

- Stress Analysis: Identifying weak points in structures to prevent failure and improve longevity.

- Pipe Stress Analysis: Assessing pipeline resilience under thermal, mechanical, and environmental stresses to ensure safety and reliability.

- Non-Linear Analysis: Simulating complex material behaviors, such as plasticity, creep, and high-temperature exposure, ensuring compliance with operational requirements.

- Fatigue and Fracture Mechanics: Determining failure risks and extending operational lifetimes.

Additional Capabilities:- Fitness for service assessments for critical infrastructure.

- Failure Assessment and risk-based evaluations.

- Ansys Structural Analysis for industry-leading simulation accuracy.

- Seismic and vibration analysis for industrial structures.

- Design Optimization using Finite Element Method Analysis to enhance performance and reliability.

What is Finite Element Analysis?

Finite Element Analysis (FEA) is a powerful computational tool used to predict how products and materials behave under real-world forces, vibrations, heat, and other physical effects. By breaking down complex structures into smaller, manageable elements, FEA provides precise insights into stress, deformation, and performance—optimizing designs for safety, efficiency, and cost-effectiveness.

Call For a Quote:

+44(0)7550680067

F.A.Q.

What types of engineering challenges can FEA solve?

FEA is ideal for analyzing structural integrity, thermal performance, vibration patterns, and fluid dynamics in complex systems. It helps predict failure points, optimize material usage, validate safety compliance, and simulate real-world conditions—from aerospace component stress tests to automotive crash simulations.

Which industries benefit most from FEA services?

Our FEA expertise spans:

-

Aerospace: Wing stress analysis, turbine blade thermal studies

-

Automotive: Crashworthiness simulations, suspension load testing

-

Energy: Pipeline integrity assessments, renewable energy component optimization

-

Manufacturing: Tooling fatigue analysis, production line vibration studies

How does Cygnas ensure accurate FEA results?

We combine ISO 9001-certified processes with advanced software (ANSYS, Abaqus) and proprietary validation tools. Our engineers cross-verify simulations with physical testing data and provide detailed uncertainty quantification reports for every project.